Businesses, building owners, engineers and installers worldwide confidently choose RotarexFiretec fire suppression systems and our comprehensive range of fire suppression system components and accessories. They become a world leader in fire suppression valves thanks to the expertise we’ve developed over 80 years and enduring commitment to quality and technical excellence.

Focused on innovation for fire safety systems, RotarexFiretec continue to develop breakthrough fire protection products that keep people, buildings and equipment safer from fire, creating products and systems that improve productivity, require minimal maintenance and deliver outstanding ROI over time.

RotarexFiretec gives you premium quality so you can be confident your fire detection and fire suppression system installations will achieve the highest level of safety and performance – while enabling your fire suppression system cost to fit your requirements.

Their products undergo rigorous testing by independent laboratories and have achieved key certifications including UL, FM, VdS, SP and LPCB. All Rotarex facilities are ISO 2001 and ISO 14001 certified.

- 100% performance testing for all fire suppression products

- Full traceability

- Highest quality materials

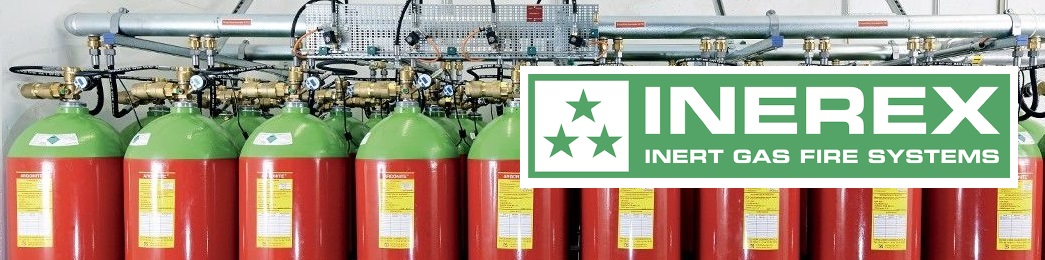

A Complete Ul-/ Fm-Approved Inert Gas Fire Suppression System

- Improve accuracy with digital measurement

- Always know your system is armed and ready

- Prevent false reads due to temperature variations

- Proactively send warnings when the system needs attention

- Now available with convenient remote monitoring options

- Is resistant against vibrations

Constant Discharge Pressure Regulator

Reduces discharge pressure to a pre-set pressure (60 bar)

Attaches to the valve discharge port

Helps reduce pressure blow-outs and venting requirements

Fire Suppression System Using 3m™Novec™1230 Fire Protection Fluid

A TURNKEY SOLUTION

All the components you need to configure a complete CLEANFIRE Clean Agent total flooding fire suppression system

PROVEN PERFORMANCE

VdS-approved system

Already protecting thousands of installations worldwide

SAVES TIME AND EFFORT

Commercial Kitchen Fire Suppression System

COMPLETE PRE-ENGINEERING SYSTEM

Designed to protect commercial kitchens

FULLY AUTOMATED

Automatically detects and suppresses fire, No electricity needed

QUICK DETECTION

Protects cooking zones, directly above where a fire can start.

A complete system: all the compatibility, validation, and testing work is already done for you.

1. Quick & Easy installation directly above high-risk cooking areas:

The flexible sensor tubing is easily installed directly inside the extractor hood – directly above cooking areas.. When in service, the tubing is pressurized with dry nitrogen to 16 bar. The dynamics of pressurization make the tubing more reactive to heat.

2. Early fire detection:

If a flame-up occurs, the heat of the fire causes the pressurized Sensor tube to burst at the hottest spot (approx. 175°C).

3. Instant suppression:

The sudden tube depressurization actuates the special pressure differential valve and instantly floods the cooking area with Class F extinguishing agent. The fire is quickly suppressed just moments after it began… minimizing damage and downtime.

A Complete Fire Suppression System For Vehicle Engines

A COMPLETE PRE-ENGINEERED SYSTEM

Designed to protect Vehicle Engines from fire

Everything you need together in one box

ULTRA-COMPACT

The most compact system to win the UNECE certification

Protects engine cavities of 4m3 with just 4L of agent

UNECE R107 and RISE APPROVED

Tested and Certified according to UNECE R107 Standards for passenger bus engines

FULLY AUTOMATIC

Automatically detects and suppresses fire

No electricity required

1. Quick & Easy installation directly inside electrical cabinets:

The flexible sensor tubing is easily installed directly above and around the engine – closer to where a fire could start. When in service, the tubing is pressurized with dry nitrogen to 16 bar. The dynamics of pressurization make the tubing more reactive to heat.

2. Early fire detection:

If a fire occurs, the heat of the fire causes the pressurized sensor tube to burst at the hottest spot (approx. 110°C)

3. Instant suppression:

The sudden tube depressurization actuates the special pressure differential valve and instantly floods the entire engine compartment extinguishing agent. The fire is quickly suppressed just moments after it began… minimizing damage and downtime.

A COMPLETE PRE-ENGINEERED SYSTEM

Designed to protect Electrical Enclosures and Circuitry

Everything you need together in one box

FULLY AUTOMATIC

Automatically detects and suppresses fire, No electricity required

FAST DETECTION

Installs directly INSIDE electrical cabinets – closer to where a fire can start

UL and FM-approved systems available

1. Quick & Easy installation directly inside electrical cabinets:

The flexible sensor tubing is easily installed inside the electrical cabinet – directly above the wires and circuity where a fire could start. When in service, the tubing is pressurized with dry nitrogen to 16 bar. The dynamics of pressurization make the tubing more reactive to heat.

2. Early fire detection:

If a flame-up occurs, the heat of the fire causes the pressurized sensor tube to burst at the hottest spot (approx. 110°C).

3. Instant suppression:

The sudden tube depressurization actuates the special pressure differential valve and instantly floods the entire cabinet area with CO2 extinguishing agent. The fire is quickly suppressed just moments after it began… minimizing damage and downtime.

A Complete Fire Suppression System For CNC Machines

A COMPLETE PRE-ENGINEERED SYSTEM

Designed to protect CNC Machining cabins

FULLY AUTOMATIC

Automatically detects and suppresses fire

FAST DETECTION

Installs directly INSIDE CNC Machining cabins – closer to where a fire can start

UL and FM-approved systems available

1. Quick & Easy installation directly inside CNC machines:

The flexible sensor tubing is easily installed directly on the walls and roof of the machining enclosure. When in service, the tubing is pressurized with dry nitrogen to 16 bar. The dynamics of pressurization make the tubing more reactive to heat.

2. Early fire detection:

If a flame-up occurs, the heat of the fire causes the pressurized sensor tube to burst at the hottest spot (approx. 110°C)

3. Instant suppression:

The sudden tube depressurization actuates the special pressure differential valve and instantly floods the entire cabinet area with CO2 extinguishing agent. The fire is quickly suppressed just moments after it began… minimizing damage and downtime.